Coal Grinding Station

Interrelationship of coal grinding properties and coal

1998年8月1日 The Hardgrove grindability index (HGI) is a widely used coalquality parameter with applications in coal mining, beneficiation, and utilization An 2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalAn investigation of performance characteristics 2024年7月25日 Indirect firing coal grinding systems are designed to enhance the combustion efficiency and safety of coalfired boilers and furnaces Unlike direct firing Indirect Firing Coal Grinding Systems: Enhancing Efficiency 2015年3月1日 Coalspecific and machinedependent parameters are incorporated in the VSM model • Enable simulations on changes in coal breakage property and operational Modelling of vertical spindle mills Part 2: Integrated models

The Evolution of the Modern Coal Grinding System IEEE

The modern indirect coal grinding system can operate with either hot gases from the kiln hood/cooler or from the discharge of the preheater tower The firing circuit has been 2024年7月16日 Buying a standalone coal system In cases in where a coal grinding system is purchased as a standalone unit as part of an expansion, retrofit or change in Safety considerations when purchasing a standalone 2021年4月27日 COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS Most rotary kilns use solid fuels as the main heat source to produce cement clinker A training COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS2022年2月24日 The study reveals that the lowest specific energy consumption is achieved when the relative rotational speed of the mill is between 081 and 087; the weighted average diameter of the balls Improving the efficiency of the coal grinding

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 PDF Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) Find, read and cite all the research2015年3月1日 Coalspecific and machinedependent parameters are incorporated in the VSM model • Enable simulations on changes in coal breakage property and operational conditions • A tool for power station PF grinding troubleshooting, optimisation and controlModelling of vertical spindle mills Part 2: Integrated models 2021年3月12日 At the GPSE test station, extensive test series with the semiindustrial mill type MPS 40 B (refer to Figure 3) are conducted for the grinding of different solid fuels to determine the basic rating data With MPS mills for coal grinding AYS Engineering2024年8月22日 The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well For both mills a constant centrifugal force is maintained The speedA Comparison of Three Types of Coal Pulverizers

Emergency inerting systems for coalgrinding applications

2011年10月21日 In the case of coalgrinding or storage (as one might find in a cement plant) it is not possible to remove the fuel (coal) or ignition source (grinding energy, heat, static charges) and so one has to concentrate on removing the third necessary component O 2 This fact has given rise to inerting systems that rely on the use of inert gasesThe Hardgrove grindability index (HGI) is a widely used coalquality parameter with applications in coal mining, beneficiation, and utilization An understanding of the petrology of the coal is fundamental to understanding the validity of the HGI in the given application The HGI varies with coal rank, increasing (greater ease of grinding) with increasing rank Interrelationship of coal grinding properties and coal 2018年3月5日 Coal analysis was done on hard grove grind ability, abrasive indices and calorific value of coal The effect of low calorific value coal was Secondly I would like to thank the Station management for allowing me to carry out a study on the mills Special thanks must go to Muzi Myeza and Sibusiso Nxumalo who encouragedPerformance optimisation of vertical spindle coal Download Citation On Oct 14, 2020, Yanping Li and others published A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM Find, read and cite all the research you need on A Wear Condition Monitoring Model of Coal Mill Grinding

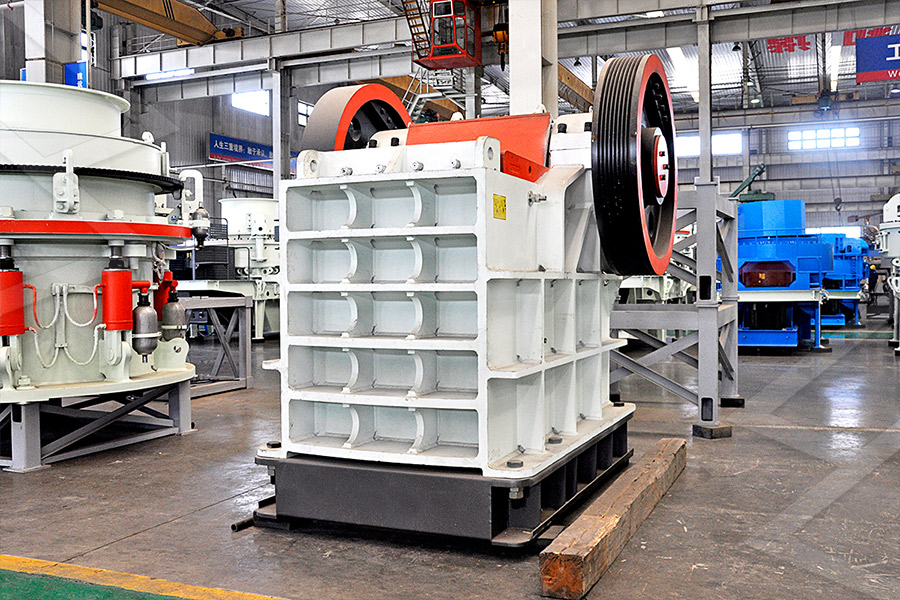

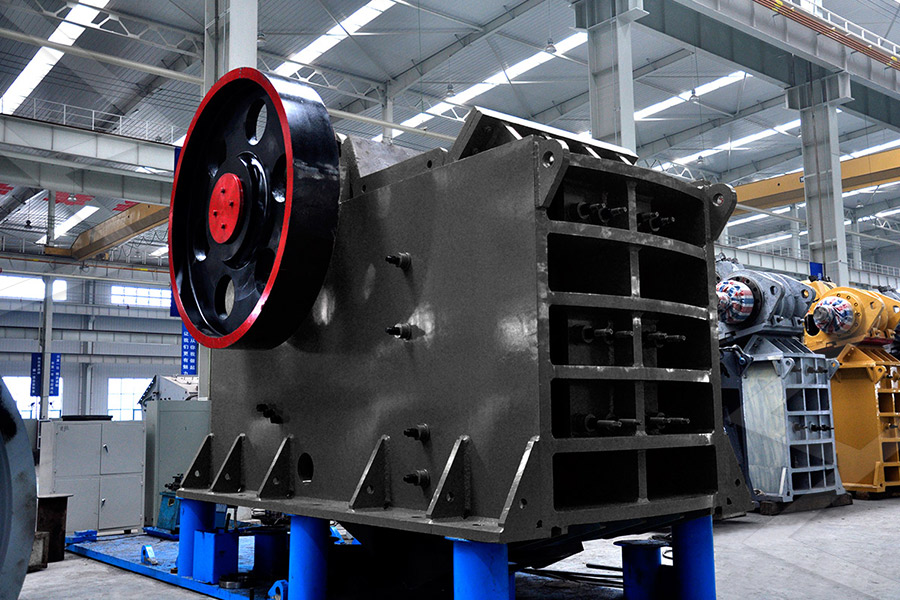

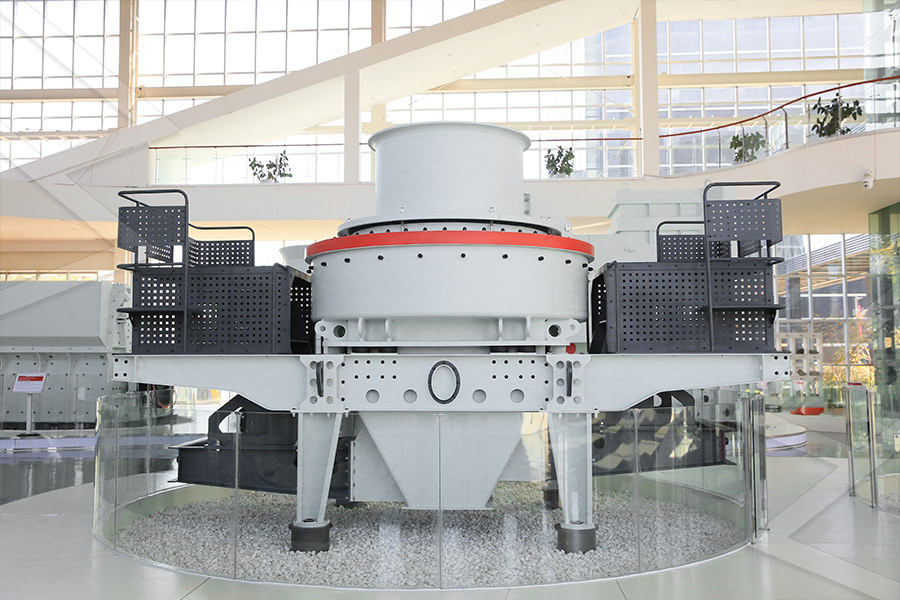

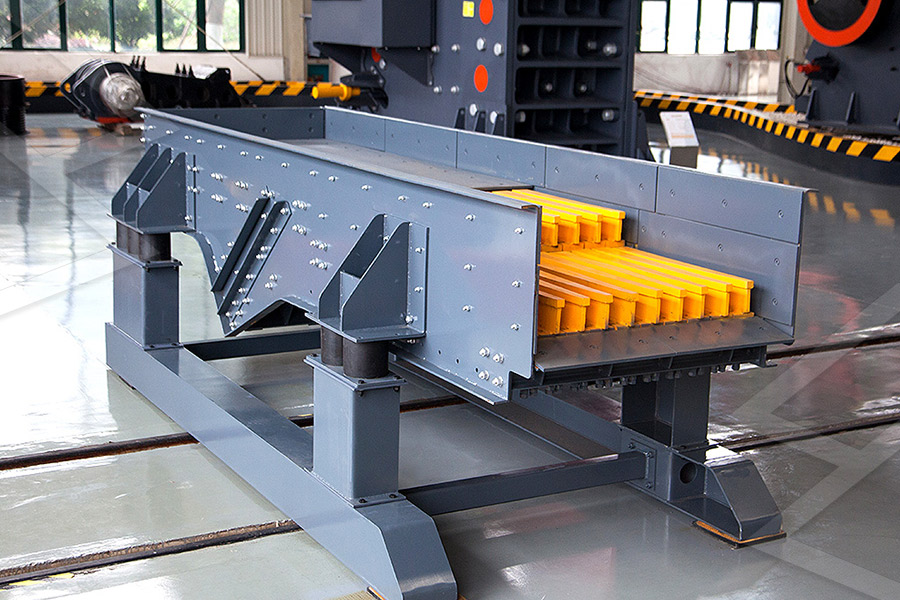

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 In addition, the entire coal processing plant must be considered to make the coal crushing plant compatible with the equipment of the screening plant, powder grinding plant, and coal wash plant, such as vibrating screens, coal mills, rotary dryers, etc The following are commonly used equipment combinations in the coal crushing plants:2002年1月1日 Extensive tests in the coal grinding test field and in the flow laboratory, form together with the advanced CFD calculations as well as operating experience with over 2000 operating MPS ring and A new MPS® mill for the Veltheim Power Station2016年12月19日 also find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) describes its vertical roller mills for coal grinding and provides a case study of an MPS225BK installed at CBR’s Lixhe cement works in Belgium COAL GRINDING Figure 1: MPS coal grinding mill with SLS highefficiency COAL GRINDING IMPS: more than meets the eye GebrJiangsu Pengfei Group Co,Ltd Add:Benjia,Ji,North Suburbs of Hai'an County,Jiangsu Province,PRC: Contact Person:MrChen XiaoFeng: Mobile Phone:990PENGFEI Famous Cement Machinery Manufactory Of China

COAL HANDLING SAFETY Land Instruments International

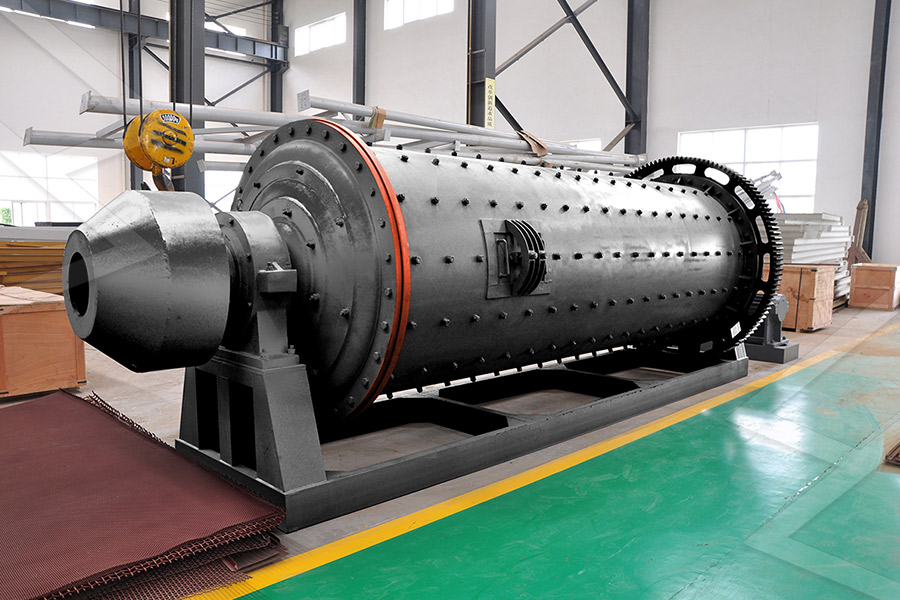

2020年6月19日 STRENGTHENING PLANT SAFETY IN COAL GRINDING MILLS AND STORAGE SILOS WITH CARBON MONOXIDE MONITORING All coals oxidise during storage, but sub bituminous coals (such as Power River Hoosier Energy’s Merom Generating Station in Indiana, USA, is a coalfired baseload plant with two 535 MW 2014年5月1日 A 250 kg coal sample was obtained from Tutuka power station in South Africa to do grinding kinetics tests Eight single size classes as specified in Table 2 were prepared at Wits University Eight single size classes as specified in Table 2 were prepared at Wits UniversityExploring ball size distribution in coal grinding mills2022年12月19日 The preparation and application of ultraclean coal is one of the important aspects of clean energy technology However, the preparation of ultraclean coal is mainly chemical methods, which are low in efficiency, high in energy consumption and expensive It is urgent to find an effective method to prepare ultraclean coal In this paper, the Production of UltraClean Coal by the Combined Method of Grinding 2014年5月1日 A 250 kg coal sample was obtained from Tutuka power station in South Africa to do grinding kinetics tests This is not a trivial problem and a detailed programme of experiments to characterise how increase in stone:coal ratio affects the grinding process is required This is a problem that we hope to tackle in one of the coal plants in the Exploring ball size distribution in coal grinding mills

Sustainability of coal mines: Separation of clean coal from

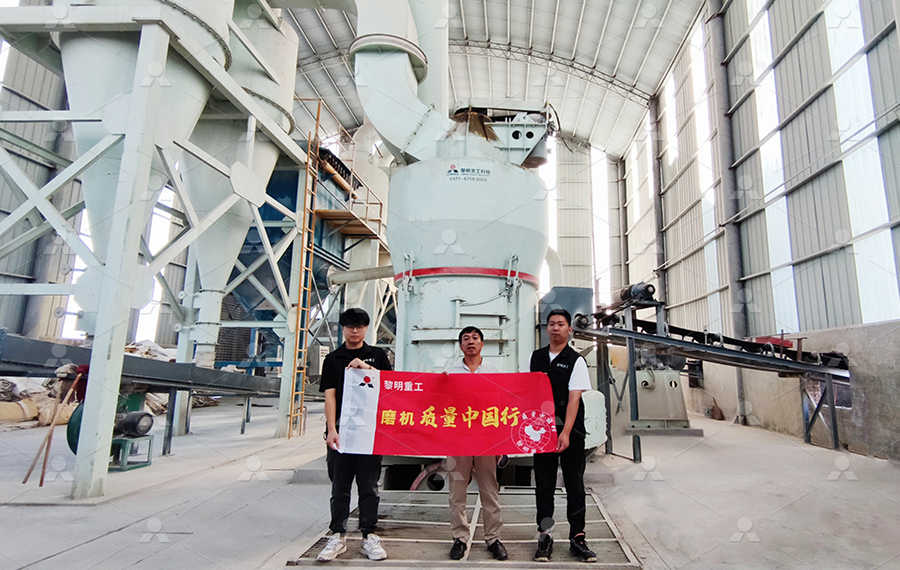

2021年5月1日 From Fig 6 a, it can be concluded that the average particle size (206 μ) obtained from wet grinding was much lower compared to the average particle size (1066 μ) obtained from dry grinding In case of CoalB, wet grinding resulted ultrafine coal slurry with an average particle size of 217 μ, whereas dry grinding resulted in coal powder 2015年11月1日 The physical processes associated with mills such as grinding, coal entrainment, drying, heat transfer, and classification are modeled Internal structure of the mill is divided into four zones and coal is differentiated into ten size groups From the validation results, it is concluded that the model fits the onsite measured data very well A unified thermomechanical model for coal mill operation2021年8月24日 sufficient coal reserves available to keep the power station in operation should the mine experience production problems Inside the power station, the coal is pulverised to a fine powder in giant grinding mills This is because pulverised coal burns quickly, like gas The pulverised coal is transported to the boiler furnace with air where it HOW ELECTRICITY IS PRODUCED AT A COALFIRED China Slag grinding station catalog of Pfrm2800s Slag Coal Clinker Cement Pet Coke Limestone Grinding Vertical Mill, Slag Grinding with Vertical Roller Mill in China provided by China manufacturer Jiangsu Pengfei Group Co, Ltd, page1Slag grinding station Jiangsu Pengfei Group Co, Ltd

Maximizing wear resistance of balls for grinding of coal

2007年9月10日 24 Wear testing procedureThe tests were performed according to the following steps: (1) Runin: The balls were submitted to 30 h of wear in the pilotplant ball mill, grinding coarse quartz sand (03–25 mm) This step provided the removal of a layer of about 100 ; μm, thus removing oxide scales and other defects from the surface (2)2024年9月6日 coal grinding plant; process and nonprocess equipment rotary kiln dryer; preheater; vertical mill and ball mill; material handling systems; storage systems; deha tech > portfolio > completed projects TASHKENT 100TPH CEMENT GRINDING 2024年7月25日 Publications and Interviews Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing Evaluation of Existing Systems for Safety Coal 2011年8月1日 Now suppose this same pulverizer must grind sufficient coal flow to produce full load on the boiler with fuel that is 40 HGI, still 3/4inch maximum size with 7% moisture, but with an increased Pulverizers 101: Part I POWER Magazine

Fire and explosion protection of coal grinding systems

2024年7月25日 You will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grinding2021年5月1日 Accurately characterizing the pore structure of tectonically deformed coal (TDC) is an essential prerequisite for investigating the porosity change rules of coal during coal deformation This paper aims to discuss the possibility of conducting gas adsorption on original coal chunks of TDCs instead of ground coal particles and to investigate the Influence of mechanical grinding on characterization of Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems Grinding SpringerLink

Innovation design of underground water treatment station in Yadian Coal

2017年2月22日 Combining with the actual situation of Yadian Coal Mine, the arrangement form of ground and undergroundl water treatment station were compared, so were the traditional water treatment technology 2019年10月23日 Today, a coke battery with coal ramming is under construction at PAO Severstal In introducing ramming technology, equipment in the coal preparation and coke sorting shops must be constructed or reconstructed With ramming, the moisture content of the coal batch is 100–115% Crushing ensures that 90 ± 1% of the coal is within the ≤3 Innovations in Coal Preparation and Coke SortingKey words: coal, modeling of grinding process, grain size distribution, MaxwellBoltzmann law, numerical prediction INTRODUCTION The development of humankind is inseparably connected with the use of energy, whose generation involves the use of energy rawmaterials Currently, fossil fuels, such as hard coal, brown coal, petroleum and natMODELING OF THE PROCESS OF COAL GRINDING Srce2020年4月21日 Grinding, as an important preparation step for beneficiation is very necessary to study for the finely disseminated extent, vanadiumbearing stone coal with complex chemical composition In this paper, grinding medium, time, degree and monomer dissociation degree were investigated in detail The results show that the efficiency of rod Influences of Grinding on the Classification and Enrichment

(PDF) Effect of Biomass Carbonization on the Grinding of Coal

2020年8月21日 The results of the research showed that the joint grinding of coal and biomass contributes to the achievement of the minimum size of coal and wood and, as a result, leads to an increase in the Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm) Conveying to Hoppers: Covered belt conveyors, horizontal or inclined are most suitable and commonly used for conveyingCoal Grinding Cement Plant OptimizationBW's coal pulverizers and mills set the standard for quality, durability, and superior performance, capable of accommodating a wide variety of coals and load swings to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability Reliable Coal Pulverizers and Mills » Babcock Wilcox2018年10月23日 Table 3 Effect of Rod Size and Ouanity and Grinding Time at 80 rpm on Coal Particle Size Distribution (Cumulative Percentage Retained) SNo Sieve 20 tIn, diam Rods 35 '/'in diam Rods 80 y,In, diam Rods size, urn Grind ing Time (min) Grind ing Time (min) Grinding Time (min) 5 10 15 20 5 10 15 20 5 10 15 20Dry grinding studies of coal in a rod mill Springer

Analysis of coal Mill Dynamic Characteristics Under Normal

1997年8月1日 The model is based on mill input/output mass and energy conservations Particular attention in model development was placed on the coal grinding process since the slow mill coal grinding process is a dominant factor affecting mill dynamics The effect of raw coal size distribution on mill dynamics was also considered in the model development2013年2月1日 As such the coal pulveriser is truly the 'heart' of the combustion process for a coalfired power station Coal pulveriser design In general, coal pulverisers are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 per cent moisture and achieving a discharge fineness of 70 per cent Coal pulverisation with vertical roller mills Engineer Live2013年4月18日 Wear characteristics and design optimisation of grinding elements for vertical mills Ken Birchett reports Coal pulverisation is essential to the overall system process of a coalfired power station, not just in terms of furnace performance and heat rate but in terms of the mechanical reliability and integrity of the furnaceGrinding elements maximise pulveriser operating Engineer 2015年3月1日 Coalspecific and machinedependent parameters are incorporated in the VSM model • Enable simulations on changes in coal breakage property and operational conditions • A tool for power station PF grinding troubleshooting, optimisation and controlModelling of vertical spindle mills Part 2: Integrated models

MPS mills for coal grinding AYS Engineering

2021年3月12日 At the GPSE test station, extensive test series with the semiindustrial mill type MPS 40 B (refer to Figure 3) are conducted for the grinding of different solid fuels to determine the basic rating data With 2024年8月22日 The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well For both mills a constant centrifugal force is maintained The speedA Comparison of Three Types of Coal Pulverizers2011年10月21日 In the case of coalgrinding or storage (as one might find in a cement plant) it is not possible to remove the fuel (coal) or ignition source (grinding energy, heat, static charges) and so one has to concentrate on removing the third necessary component O 2 This fact has given rise to inerting systems that rely on the use of inert gasesEmergency inerting systems for coalgrinding applicationsThe Hardgrove grindability index (HGI) is a widely used coalquality parameter with applications in coal mining, beneficiation, and utilization An understanding of the petrology of the coal is fundamental to understanding the validity of the HGI in the given application The HGI varies with coal rank, increasing (greater ease of grinding) with increasing rank Interrelationship of coal grinding properties and coal

Performance optimisation of vertical spindle coal

2018年3月5日 Coal analysis was done on hard grove grind ability, abrasive indices and calorific value of coal The effect of low calorific value coal was Secondly I would like to thank the Station management for allowing me to carry out a study on the mills Special thanks must go to Muzi Myeza and Sibusiso Nxumalo who encouragedDownload Citation On Oct 14, 2020, Yanping Li and others published A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM Find, read and cite all the research you need on A Wear Condition Monitoring Model of Coal Mill Grinding2023年10月8日 In addition, the entire coal processing plant must be considered to make the coal crushing plant compatible with the equipment of the screening plant, powder grinding plant, and coal wash plant, such as vibrating screens, coal mills, rotary dryers, etc The following are commonly used equipment combinations in the coal crushing plants:6 Types of Coal Crusher: Which Is Best for Crushing My Coal?2002年1月1日 Extensive tests in the coal grinding test field and in the flow laboratory, form together with the advanced CFD calculations as well as operating experience with over 2000 operating MPS ring and A new MPS® mill for the Veltheim Power Station

COAL GRINDING IMPS: more than meets the eye Gebr

2016年12月19日 also find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) describes its vertical roller mills for coal grinding and provides a case study of an MPS225BK installed at CBR’s Lixhe cement works in Belgium COAL GRINDING Figure 1: MPS coal grinding mill with SLS highefficiency