Information About Crushing Stone

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small stones, sand dust and gravels Enormous amount of work has been performed beforehand to 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working The Complete Guide to Primary Crushing, 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock Types of Crushers: Choosing the Right One for Each Stage2022年5月13日 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small Stone Crushers: A Technical Review on Significant Part of

Experimental study of crushing process of the crushed

2021年2月5日 In general, crushed stone production consists of three stages: extraction of raw materials, crushing, and sorting by fractions Crushed stone is obtained quite simply April 19, 2024 1:42 pm What Are Rock Crushers and How Do They Work? Crushers are key equipment in mining, construction and aggregate industries They break large rocks, ore, or other materials into smaller, Types of Crushers Explained: Everything You Crushing stone efficiently requires a welldesigned process and the right combination of crushing equipment and screeners By understanding the options available and their The Ultimate Guide on How to Crush Stone2024年3月7日 Explore the pivotal role of crushed stone aggregates in construction, from providing structural stability to enhancing drainage systems Discover the economic and environmental advantages of using Crushed Stone Aggregates for Construction: The

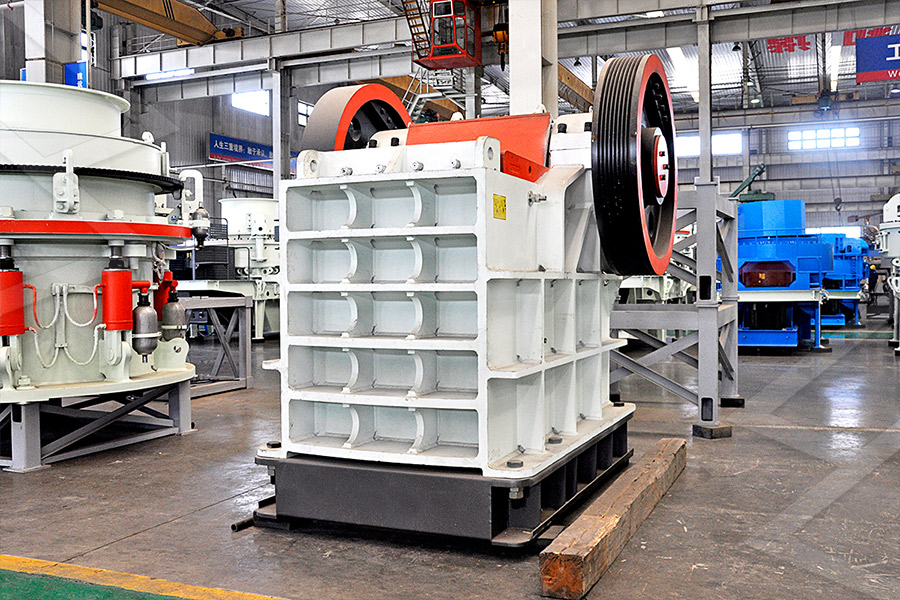

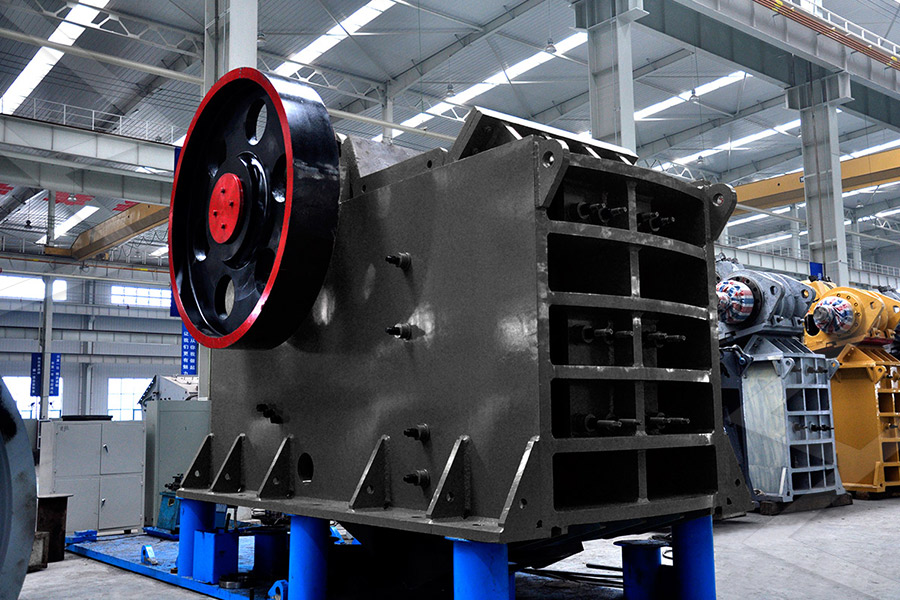

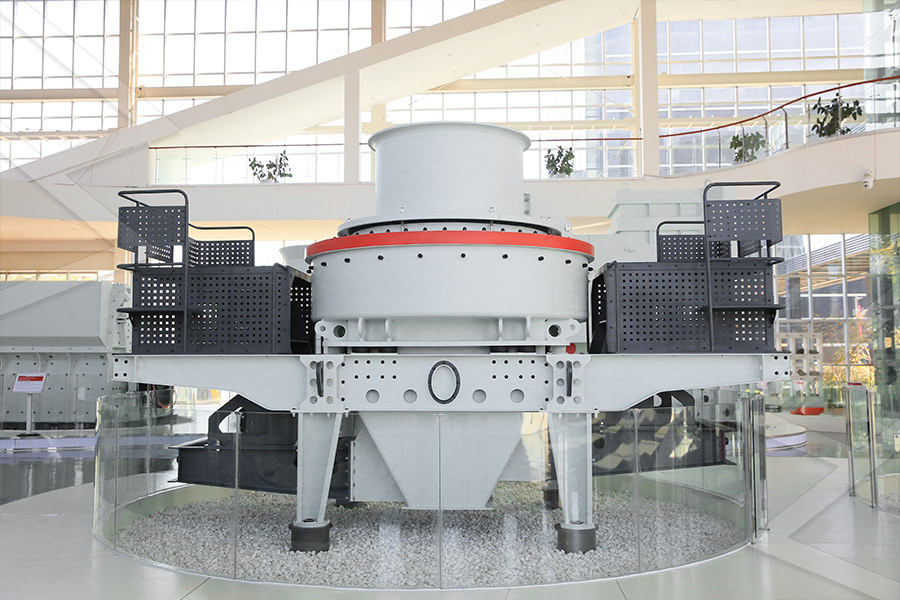

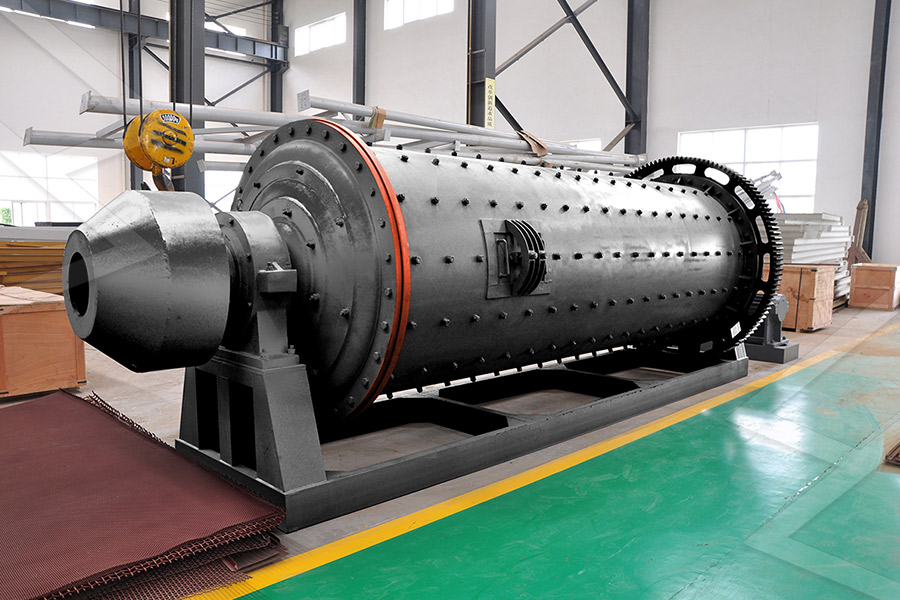

5 Types Of Stone Crushers Application and

Stone crusher is mainly used for crushing operation in quarry crushing plant and mining plant There are 5 types of stone crushers: jaw crusher, impact crusher, hammer crusher, cone crusher, and VIS crusher3 天之前 So, SWL describes a nonsurgical technique for treating stones in the kidney or ureter (the tube going from the kidney to the bladder) using highenergy shock waves Stones are broken into "stone dust" or fragments that are small enough to pass in urine lf large pieces remain, another treatment can be performedKidney Stone Treatment: Shock Wave Lithotripsy2024年8月30日 In Civil Engineering and Construction Industry, crushed stones are known as aggregates and are the basic materials in modern construction work The current methods for crushing stones to produce aggregates are characterized by the use of large, expensive and centralised crushing plants, which are beyond the reach of small scale ASSESMENT OF STONE CRUSHING CHARACTERISTICS AND DEVELOPMENT OF A STONE 2018年12月26日 Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing methodsConstruction, Working and Maintenance of Crushers for

Stone Crusher Plant Design: Best Practices for Efficient Crushing

2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance priorities Learn how to optimize crushing operations and minimize environmental impact for efficient and effective production2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of The Complete Guide to Primary Crushing, Secondary CrushingCrush testing is a method used to evaluate a material’s resistance to compressive forces or crushing It involves the application of controlled compressive loads to a sample or specimen and monitoring its response to these forces Additional Information About Crush Testing Crush testing is continually evolving, with ongoing research and Crush Testing: Comprehensive Guide to Understanding2020年7月27日 The information below provides a general overview to help you choose the right material for your project Crushed Stone Grade 110 Generally, as the grade number goes up, the size of the stone goes down #1 – The # 1 crushed stone grade is the largest of the crushed stone grades and includes stone between 24 inches long7 Different Crushed Stone Sizes and Their Applications ReAgg

MADEN Machinery Crushing Screening

Stone crushing can be both economical and environmentally friendly In addition, stone crushers can be used to convert old building materials into new building materials As a result, the use of stone crushers in the mining and quarrying industry is not only necessary, but also beneficial in terms of cost and environmental impact 2023年8月8日 5 dust emissions however, improper design and operation of sprinklers and improper covering is an issue Tertiary crushing: Fugitive emissions are generated during grinding of stones into fine dust Conveyor Belt: Conveyor belts are primary means of transferring raw materials and products from one end to the otherEnvironmental Guidelines for Stone Crushing Units py2008年7月22日 Primary and secondary sources describing the development of lithotripsy as a method to treat common bladder stones were reviewed RESULTS Lithotripsy emerged in the early 19th century as an alternative to the morbid and frequently fatal perineal lithotomy practised for thousands of years to relieve sufferers of bladder stones‘Crushing the stone’: a brief history of lithotripsy, the first 2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is Types of Crushers Explained: Everything You

Free Crushing Sound Effects Download Pixabay

Download crushing royaltyfree sound effects to use in your next project Royaltyfree crushing sound effects Download a sound effect to use in your next project stone fieldrecording body Pixabay users get 15% off at PremiumBeat with code PIXABAY15 Over 5 million+ high quality stock images, videos and music shared by our talented 2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, Crushing it: A Comprehensive Guide to Stone 2023年2月22日 They are used to crush large rocks, stones, and minerals into smaller pieces or gravel for various construction purposes In this article, we will discuss the different types of stone crusher machines and their applications Jaw Crusher Primary Jaw Crusher: This type of jaw crusher is used for the first stage of crushing large and hard stonesDifferent Types of Stone Crusher Machines AGICO4 天之前 Get the right permits: Stone crushing businesses often need to obtain a special permit to operate legally within their sector — and failure to comply with these requirements can cost you a hefty sum in penalties Check with your local and state authorities to ensure you have all the clearances needed to start crushingRock Crushing 101: A Beginner's Guide Senya Crushers

Occupational injuries and risk assessment among stone crushing

2023年5月13日 Background and objectives The prevalence of occupational injuries among bluecollar workers is higher in the stonecrushing industries due to highrisk and iterant nature of the work These occupational injuries, in turn, caused workers’ ill health, as well as death, which eventually diminish the gross domestic product We aimed at assessing the As the mantle moves, it crushes the material against the concave at the points where the gap is smallest (the stones in the feed are also compressed against each other – that’s known as interparticle crushing) the CSS is the final crushing zone, and is vital for determining the product size, as well as energy consumption and crusher Cone crusher basics in 4 minutes SRP2022年2月1日 And there was no better example than the lone example of crushing, or getting pressed to death, used in the United States, during the Salem Witch Trials Giles Corey Is Pressed To Death In 1692, Giles Corey was a successful farmer in the town of Danvers, Massachusetts, about 30 minutes north of Boston Unfortunately for Mr Corey, Pressed To Death: Inside The Brutal Medieval Execution 2024年7月25日 Extracorporeal shock wave lithotripsy (SWL) is a noninvasive procedure that uses shock waves to break stones in the kidney and ureter into pieces as small as grains of sand Lithotripsy is advantageous as a method of kidney stone removal because it does not require surgery, and has a 70 to 90 percent success rate in good candidatesLithotripsy Preparation, procedure, recovery, and side

Agronomy Free FullText The Application of MgO

2024年6月30日 The objective of the present study was to investigate the impact of MgO 05 g/kg loaded in different organic waste materials on the properties of the modified biochars obtained The waste materials included tea waste, wood waste, water chestnut peel, and pomegranate peel, which were used to create tea waste MgOmodified biochar 2024年3月7日 With modern crushing technologies, recycled crushed stone aggregates can match the quality of new ones This means the construction project’s strength, durability, and performance won’t be sacrificed Plus, Crushed Stone Aggregates for Construction: The This is achieved if and only if the stone crusher which will fill the demand of aggregates is designed So the design of this machine will intend to fill this demand So our main objective of the project is to design the impact stone crusher 2 DESIGN METHODOLOGY Defining the problem and gathering information regarding the crushing machine(PDF) Design of Impact Stone crusher machine Academia5 天之前 A stone crushing plant is a facility that is used to process a variety of stone materials to produce finished stone of different specifications and uses It usually consists of a feeding system, a crushing system, a screening system, and a conveying system, among others Here is a detailed explanation of how the stone crushing plant works 1 How Does A Stone Crushing Plant Work aimixgroup

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 These types of crushers are used in stone crushing plants for creating abrasive materials and quarried stones Fig 3 Working of gyratory crusher Source taken from reference Full size image 22 Secondary Crusher The secondary crushers are used as a subsidiary equipment of the stone which have been previously crushed in primary 2023年6月13日 Strength is an important property to be looked into before selecting stone as a building block Indian standard code recommends, a minimum crushing strength of 35 N/mm 2 for any building block Table 1 shows the crushing strength of various stonesDue to the nonuniformity of the material, usually, a factor of safety of 10 is used to find the Properties of Stones Requirements of Good Building Stones 2024年9月5日 Stone crushers are designed to achieve high crushing efficiency, allowing for the rapid processing of materials and increased productivity in various industrial applications Low Energy Consumption Modern stone crushers are engineered to minimize energy consumption during crushing operations, thereby reducing operational costs and Stone Crusher Crushing Rock MachineLooking for a fast, convenient solution to crushing rocks in the mining industry, inventor Eli Whitney Blake of New Haven, CT developed the first machine used for crushing stone back in 1858 Nephew of the cottongin inventor Eli Whitney, Blake had a gift for mechanical engineering, and learned his craft at his famous uncle’s arms factory Small Portable Rock Crushing Products Senya Crushers

Stone Crusher Project Report Process Business Plan PDF India

The crushing of stone happens in two different stages The first stage happens when you manually introduce and feed the 175 mm stones to the crusher, which then reduces it to anywhere around 50 mm stone pieces Then one can fit the conversion kit to the stone crusher itself, which allows it to crush that 50 mm stone piece to any smaller size Beyond the primary stone crusher and secondary crushers, screeners play a vital role in the stonecrushing process by grading the crushed material by size Screeners, or screening equipment, are integral to this process They work by sorting crushed stones into various size categories using vibrating screens or mechanical separatorsThe Ultimate Guide on How to Crush Stone2018年1月17日 Abstract Aggregate shape properties have a direct influence on the behaviour of pavement materials The crushing process is the main factor responsible for generating these shape properties; however, there has hardly been any effort directed toward optimising the performance of pavement materials by altering the crushing The influence of stone crushing processes on aggregate shape propertiesCystoscopy and litholapaxy (bladder stone crushing/removal) Patient information AZ Print this page What is the evidence base for this information? This leaflet includes advice from consensus panels, the British Association of Urological Surgeons, the Department of Health and evidence based sources; it is, therefore, a reflection of best Cystoscopy and litholapaxy (bladder stone crushing/removal)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Primary crushing is the first stage of the stone crushing process At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers Jaw Crusher2020年12月21日 In these cases, a doctor will likely recommend surgery to remove the stone This article discusses types of gallstone surgery, recovery, and aftercare Definition facts for gallstonesGallstones surgery: Types, what to expect, recovery, and 2024年8月8日 This study examines the utilization of granite stonecrushing waste in the production of porous concrete, with a particular emphasis on the influence of aggregate composition and cement paste layer thickness on the material’s strength and density Two types of aggregates were employed in this study: granite crushing screenings and granite Optimizing Porous Concrete Using Granite StoneCrushing 2023年6月11日 You might need to have a surgical procedure called shock wave lithotripsy that uses sound waves to break the stone up into smaller pieces, making it easier to pass Surgeons can also use a special camera called ureteroscope (a narrow tube with a camera at the end) to get to the stone in the ureter or kidney and break it up using laserThe 4 Stages of Passing a Kidney Stone Verywell Health

Crushing and Screening Handbook

This is 7th edition of the Crushing and Screening Handbook Please note that the data presented in the handbook is subject to change without notice Always contact for precise information about products, services or solutions To receive the Crushing and Screening Handbook, fill out your contact information on the form and click 'Submit'Types of rocks and their hardness After large rocks have been crushed into smaller stones, they can be separated by size using a screenerDifferent projects can call for different sizes of crushed stones so it may be important for you How to Crush Stone: A Simple Guide Machinery Partner3 天之前 So, SWL describes a nonsurgical technique for treating stones in the kidney or ureter (the tube going from the kidney to the bladder) using highenergy shock waves Stones are broken into "stone dust" or fragments that are small enough to pass in urine lf large pieces remain, another treatment can be performedKidney Stone Treatment: Shock Wave Lithotripsy2024年8月30日 In Civil Engineering and Construction Industry, crushed stones are known as aggregates and are the basic materials in modern construction work The current methods for crushing stones to produce aggregates are characterized by the use of large, expensive and centralised crushing plants, which are beyond the reach of small scale ASSESMENT OF STONE CRUSHING CHARACTERISTICS AND DEVELOPMENT OF A STONE

Construction, Working and Maintenance of Crushers for

2018年12月26日 Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing methods2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance priorities Learn how to optimize crushing operations and minimize environmental impact for efficient and effective productionStone Crusher Plant Design: Best Practices for Efficient Crushing 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of The Complete Guide to Primary Crushing, Secondary CrushingCrush testing is a method used to evaluate a material’s resistance to compressive forces or crushing It involves the application of controlled compressive loads to a sample or specimen and monitoring its response to these forces Additional Information About Crush Testing Crush testing is continually evolving, with ongoing research and Crush Testing: Comprehensive Guide to Understanding

7 Different Crushed Stone Sizes and Their Applications ReAgg

2020年7月27日 The information below provides a general overview to help you choose the right material for your project Crushed Stone Grade 110 Generally, as the grade number goes up, the size of the stone goes down #1 – The # 1 crushed stone grade is the largest of the crushed stone grades and includes stone between 24 inches longStone crushing can be both economical and environmentally friendly In addition, stone crushers can be used to convert old building materials into new building materials As a result, the use of stone crushers in the mining and quarrying industry is not only necessary, but also beneficial in terms of cost and environmental impact MADEN Machinery Crushing Screening2023年8月8日 5 dust emissions however, improper design and operation of sprinklers and improper covering is an issue Tertiary crushing: Fugitive emissions are generated during grinding of stones into fine dust Conveyor Belt: Conveyor belts are primary means of transferring raw materials and products from one end to the otherEnvironmental Guidelines for Stone Crushing Units py2008年7月22日 Primary and secondary sources describing the development of lithotripsy as a method to treat common bladder stones were reviewed RESULTS Lithotripsy emerged in the early 19th century as an alternative to the morbid and frequently fatal perineal lithotomy practised for thousands of years to relieve sufferers of bladder stones‘Crushing the stone’: a brief history of lithotripsy, the first