Production Of Chromium From Chromite Ore

.jpg)

Chromium (Cr) Ore Minerals, Formation,

2023年4月23日 The most common chromium ore mineral is chromite, which is a dark, black to brownishblack mineral with the chemical formula FeCr2O4 Chromite is the primary source of chromium, and it accounts 2023年10月1日 FeCr is produced from chromite ore, the most important source of virgin Cr units FeCr producers are only paid per mass unit of Cr content in the FeCr, ie in US¢/lb Chemical beneficiation of chromite ore to improve the chromium 2022年2月1日 To establish a cleaner production technology of chromium salt, the pressurized leaching process of chromite ore in 60 wt% NaOH solution, subsequent A cleaner method for preparation of chromium oxide from chromite ore The chromium (Cr) content of stainless steel originates from recycled scrap and/or ferrochrome (FeCr), which is mainly produced by the carbothermic reduction of chromite oreProcess flow chart for the production of a

Mechanism of the Direct Reduction of Chromite

In DRC, chromium (Cr) and iron (Fe) from chromite ore incongruently dissolve into a molten salt, which facilitates mass transfer to a carbon (C) reductant where in situ metallization occurs Consequently, ferrochrome 2011年4月1日 Supply of world chromite (chrome ore) has come under severe pressure over the past year driven by strong demand for ferrochrome used in ferroalloy production Chrome ore beneficiation challenges opportunities – A 2019年5月6日 The present study provides a useful set of data on the production of basic chromium sulphate from chromite ore The percent yield of sodium chromate is strongly Mineral processing: leaching process of chromium and 2016年10月31日 The experimental results show that steel scrap can be alloyed with chromium by the chromite ore in the briquettes and the Cr yield from the chromite ore increases with the increase in mill scale addition to Direct Alloying Steel with Chromium by

.jpg)

Chromite: The only mineral ore of chromium

Chromite is the only ore of chromium, a metal essential for making stainless steel, nichrome, chrome plating, pigments, refractories, chemicals and pharmaceuticalsAccording to data from the International Chromium Development Association (ICDA), global chromite ore and concentrate production totaled 294 metric tons in 2014 (Richard, 2015)Data from the US Geological Survey (USGS) estimated world production in 2014 at 29 metric tons, with South Africa at 15 metric tons, followed by Kazakhstan at 4 metric tons, Chromite an overview ScienceDirect Topics2023年10月1日 The chromium (Cr) content of stainless steel originates from recycled scrap and/or ferrochrome (FeCr), which is produced mainly by the carbothermic reduction of chromite oreChemical beneficiation of chromite ore to improve the chromium Direct reduction of chromite (DRC) is a promising alternative process for ferrochrome production with the potential to significantly reduce energy consumption and greenhouse gas emissions compared to conventional Mechanism of the Direct Reduction of Chromite

.jpg)

Top 5 Chromiumproducing Countries (Updated 2024)

2024年4月9日 1 South Africa Mine production: 18 million MT South Africa produced 18 million MT of chromium in 2023, down from the 191 million MT produced in 20222020年5月19日 Sulfuric acidbased leaching is a promising cleaner method to produce chromium salts, but its feasibility for treating low Fe(II)chromite still remains to be proven A Box–Behnken design (BBD)based set of experiments for sulfuric acid leaching of low Fe(II)chromite was utilized in this work for generating an experimental dataset for revealing the Cleaner Production of Chromium Oxide from Low Fe(II)Chromite4 天之前 Chromium is extracted from chromite ore Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4) Companies in South Africa supply chrome ore from the lower and middle group chromitites of the Bushweld complex and from the upper group chromitite seam (UG2) in addition to platinum group mineralsWhat is chromite (chrome) ore and where is it found2022年2月1日 To establish a cleaner production technology of chromium salt, the pressurized leaching process of chromite ore in 60 wt% NaOH solution, subsequent separation of a chromium salt from the leached solution and Cr 2 O 3 preparation from the intermediate product BaCrO 4 were systematically investigated, and a new highly A cleaner method for preparation of chromium oxide from chromite ore

.jpg)

CHROMITE Indian Minerals Yearbook 2020 IBM

2022年4月27日 hromite is the single commercially viable ore of chromium (Cr) which is chemically known as iron chromium oxide (FeCr 2 O 4) The properties of chromium that make it most versatile and indispensable are its resistance to corrosion, oxidation, wear galling and enhancement of hardenability Chromium is an important alloying metal2010年11月12日 Thus, the concentration of this ore was found to be useless Therefore, the study was carried out on the low grade chromite ore without concentration 2 EXPERIMENTAL Pilot plant experimental heats were carried out to produce extralow carbon ferrochromium from a domestic low grade chromite ore using the aluminothermic THE ALUMINOTHERMIC PRODUCTION OF EXTRA LOW 2019年5月6日 The current strategy reports the recovery of precious group metals (PGMs) from Na2CO3 roast of Saudi Arabian ophiolitic chromite ore at 1160 °C under atmospheric O2 The influence of roasting temperature (960–1200 °C) and leaching agents (H2O, HCl, H2SO4) and their concentrations on the recovery of PGMs was studied Chromite roast Mineral processing: leaching process of chromium and 2023年4月23日 Chromite is an oxide mineral that an iron chromium oxide with formula: FeCr2O4 It is belonging to the spinel group Chromite is the most important ore of chromium Crystals are uncommon, but when Chromite Chromium Ore, Properties, Uses and

A cleaner method for preparation of chromium oxide from chromite ore

2022年2月1日 To establish a cleaner production technology of chromium salt, the pressurized leaching process of chromite ore in 60 wt% NaOH solution, subsequent separation of a chromium salt from the leached solution and Cr 2 O 3 preparation from the intermediate product BaCrO 4 were systematically investigated, and a new highly 2020年7月27日 South African yearly chromite production has been increasing at an average production of 1 500 000t in the past 5 years except in 2016 where there was a slight decrease of approximately 900 000t [5] Conventional chromite processes achieve an average recovery of between 50 and 65%, which result in a mass yield of between 37 Beneficiation of South African chromite tailings using2021年11月1日 To establish a cleaner production technology of chromium salt, the pressurized leaching process of chromite ore in 60 wt% NaOH solution, subsequent separation of a chromium salt from the leached A cleaner method for preparation of chromium oxide from chromite ore DOI: 101016/jpsep202111052 Corpus ID: ; A cleaner method for preparation of chromium oxide from chromite ore @article{Tian2021ACM, title={A cleaner method for preparation of chromium oxide from chromite ore}, author={Yijuan Tian and Xuejun Quan and Gang Li and Xiaoyu Tang and Xianfeng Qin and Haifeng Wu and Kui Zeng and A cleaner method for preparation of chromium oxide from chromite ore

Mineral Commodity Summaries 2022 Chromium

2022年1月31日 Domestic Production and Use: In 2021, the United States was expected to consume 5% of world chromite ore production in various forms of imported materials, such as chromite ore, chromium chemicals, chromium ferroalloys, chromium metal, and stainless steel Imported chromite ore was consumed by one chemical company to produce 2023年5月18日 tion of chromium ore and the problems of resource recovery, environmental pollution, and CO 2 emissions METHODS Definitions and Boundaries In this study, the system boundary is defined as a country, and the object of the analysis is chromium ore (Fig 4) The chromium cycle can be divided into the four stages, namely Exploring Chromium Ore Consumption: New 2011年4月1日 Sources of chromite Chromium ore occurs exclusively in rocks formed by the intrusion and solidification of molten lava or magma which is very rich in the heavy, iron containing minerals such as pyroxenes and olivines The chromium spinel is a heavy mineral and it concentrates through gravity separation from most of the other molten material in Chrome ore beneficiation challenges opportunities – A 2014年9月9日 Chromite as a method for producing a chromiumiron alloy suitable for direct steel from ore, chromite a derivative of the ore is agglomerated with a carbon fine powder, and the addition of the accelerator and the binder, the dry aggregate of natural at an elevated temperature suitable for reduction as a reducing agent by being supplied to the Production of chromium iron alloys directly from chromite ore

.jpg)

Chromite Ore an overview ScienceDirect Topics

Chromite Chromium from ores of chromite is used to make essential stainless steel, tool steel, armorpiercing projectiles, and is used in other hightemperature applications estimates are that over 6000–7000 Mt of chromite ore production goes out amounting to over $400,000, with lost revenues to the government each day of more than 2016年1月20日 Ferrochromium and chromium based compounds are produced worldwide from chromite oreChrome chemicals are from chromium based compounds Basicchromiumsulfate (BCS) is a chrome chemical mostly required as main tanning agent in chrome tanning process in leather industry and also to synthesize other chromic Cleaner production of basic chromium sulfate ScienceDirect2022年12月2日 Domestic Production and Use: In 2022, the United States consumed an estimated5% of world chromite ore production in various forms of imported materials, such as chromite ore, chromium chemicals, chromium ferroalloys, chromium metal, and stainless steel Imported chromite ore was consumed by one chemical company to produce Chromium USGS Publications Warehouse2006年1月1日 The traditional process does not extract all of the chromium from the chromite ore The residue contains unreacted chromite ore and unextracted chromate, and usually must be disposed of onsite The chromiumcontaining sodium sulfate (Na 2 SO 4) formed as a byproduct has little commercial value and also must be disposed of onsite 3Development of a new cleaner production process for producing chromic

Microwave and Conventional Carbothermic Reduction of Chromite Ore

2024年2月3日 Chromite ore is the sole commercial source of chromium which is mainly present in the form of spinel containing multiple metal elements with the chemical formula of (Mg,Fe)(Cr,Al,Fe) 2 O 4 [1,2,3]Depending on its content of Cr 2 O 3 and the mass ratio of Cr/Fe, chromite ore can be used in the fields of metallurgy, chemicals, and refractories 2011年5月7日 The primary objective of this study is to demonstrate an efficient and optimum way to recover chromium and iron from chromite ore processing residues (COPR) for the production of chrome steel and stainless steel In Hudson County, New Jersey, there are more than two million tons of leftover COPR Part of COPR was used as fill materials Chromium steel from chromite ore processing residue — A The mining and treatment of chromite ore along with industrial applications of its compounds generate abundant solid and liquid chromium wasteProduction of chromite ore from Odisha The principal and commercially viable ore is chromite, \(\ce{FeCr2O4}\), which is found mainly in southern Africa (with 96% of the worlds reserves), the former USSR and the Philippines More than half the production of chromium goes into metallic products, and about another third is used in refractories It is an ingredient in several 217A: Chromium Metal Chemistry LibreTexts

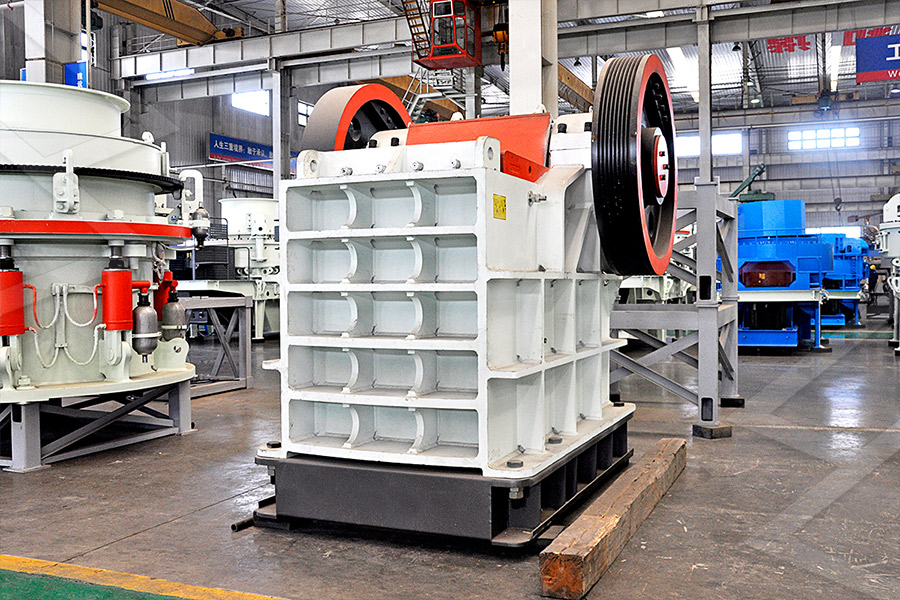

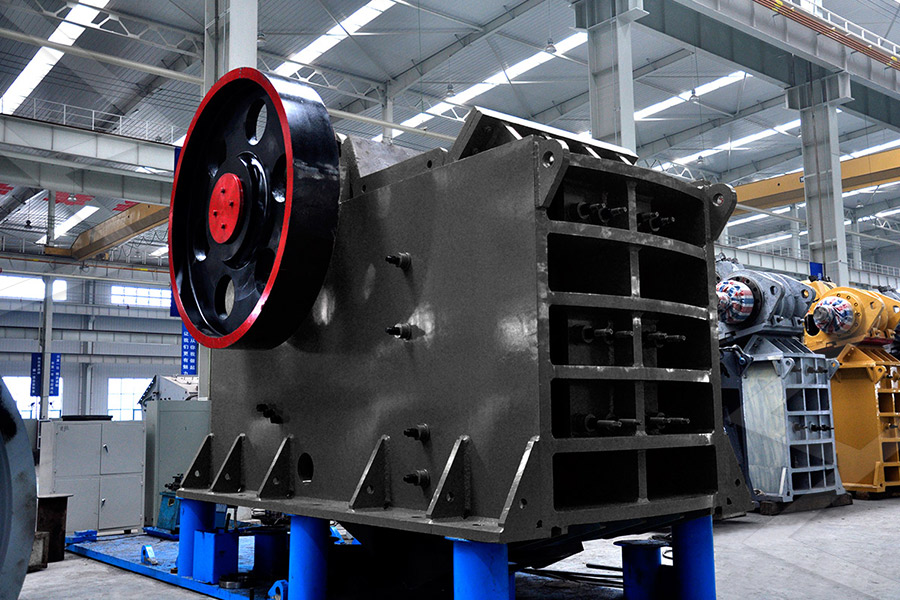

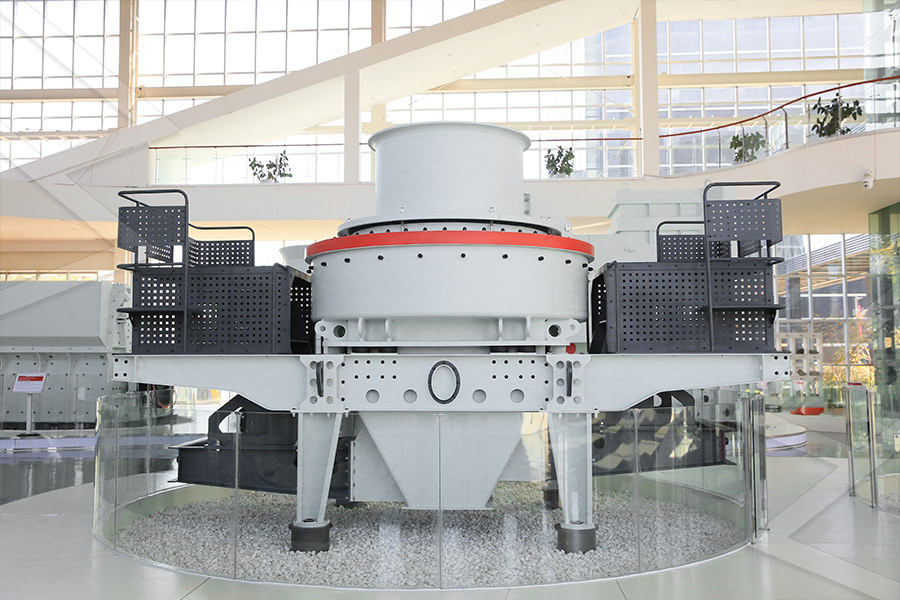

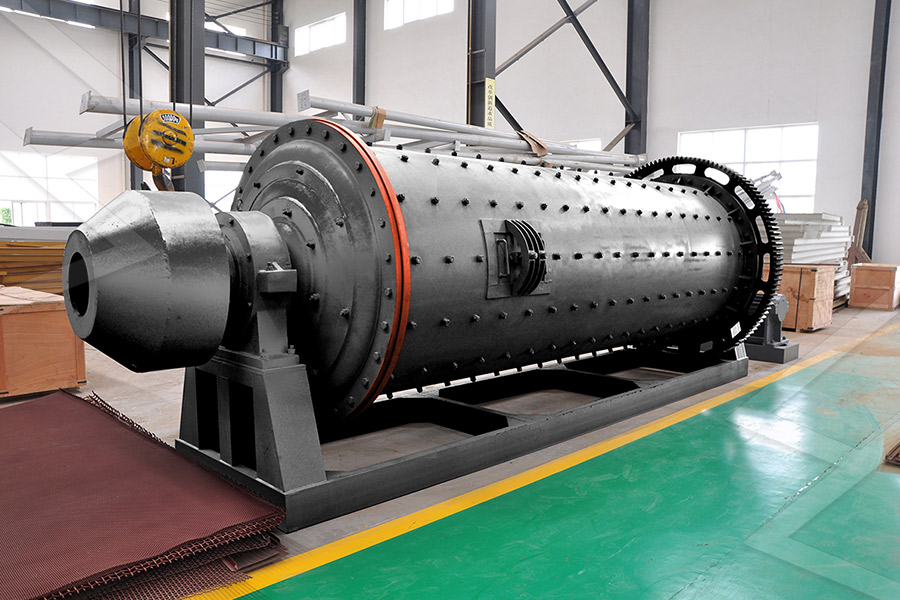

Chromium (Cr) Definition, Preparation, Properties, Uses

2024年6月28日 Chromium production begins with the mining of chromite ore (FeCr2O4), which is the main source of chromium This process involves extracting chromite from open pit or underground mines After mining, the chromite ore is initially concentrated through various processes including crushing, grinding, and gravity separation to enhance its If secondary chromium production is used, the external dependence rate of chromium will drop to more than 69% Conclusions The supply and demand situation of chromium in China will still be severe, and the gap still needs to be supplemented by a large number of imported ores from 2021–2035 CHE Dong, YAN Qiang, WU Qing Chromite ore Chromite ore resources characteristic and analysis of supply 2023年6月28日 Chromite ore (also known as chrome ore) is used in the metallurgical industry to make chromium ferroalloys and metals It is also used in the chemical industry to produce sodium dichromate, which is a Chromium Ore, Chromite, Properties, Uses, 2023年5月1日 Chromite is the most important chromium ore mineral It forms a complete solid solution series with many other members of the group, eg in the ChromiteHercynite Series, ChromiteSpinel Series, Current Chromite Prices From International,

Mineral Commodity Summaries 2024 USGS

2024年1月30日 Domestic Production and Use: In 2023, the United States consumed an estimated 4% of world chromite ore production in various forms of imported materials, such as chromite ore, chromium chemicals, ferrochromium, chromium metal, and stainless steel Imported chromite ore was consumed by one chemical company to produce chromium Chromite ore processing residue (COPR), derived from the socalled high lime processing of chromite ore, contains high levels of Cr(III) and Cr(VI) and has a pH between 11 and 12 Ferrous sulfate, which is used for remediation of Cr(VI) contamination in wastewater and soils via reduction to Cr(III) and subsequent precipitation of iron(III)/chromium(III) Chromium Remediation or Release? Effect of Iron (II) Sulfate 2017年4月28日 In a test melts, highcarbon ferrochrome is produced from chrome sinter and chromeore fines in an arc electrofurnace Two types of sinter with the best performance—the best sintering rate, strength, and product yield—are studied It is demonstrated by experimental melts that highcarbon ferrochrome can be produced from Smelting of highcarbon ferrochrome from chromium2021年8月5日 chromite ore have spurred the innovations in the technologies used for smelting chromite ore These technologies (Conventional smelting process, Outokumpu process, DC arc route, and Premus process) have been reviewed in this work Premus process has been found to be the lowestcost and most energyefficient ferrochrome Technology Innovations in the Smelting of Chromite Ore

Direct Alloying Steel with Chromium by Briquettes Made from Chromite

2016年10月31日 The experimental results show that steel scrap can be alloyed with chromium by the chromite ore in the briquettes and the Cr yield from the chromite ore increases with the increase in mill scale addition to the briquettes: the more mill scale is added to the briquettes, the lower the mass ratio of Cr to (Cr + Fe) would be, leading to a Knowledge of the chromium ore minerals proper and their associated rocksforming minerals is needed to explore new chromite fields and to predict the efficiency of individual methods for the beneficiation of chromite ores It is important also to know the physicochemical properties of individual mineral fractions of chromite ores and preparation of ore (or Chromium Ore an overview ScienceDirect Topics2006年8月1日 1 IntroductionChromate production from chromite ore is an important basic metallurgical process but is usually a source of severe pollution The traditional chromate production process used in China presently consists of three procedures: roasting of chromite ore, water leaching, and multistage evaporation and crystallizationGreen metallurgical processing of chromite ScienceDirect2018年8月20日 Nontraditional metallurgical technology of comprehensive processing of Sevan chromite (with a 43–46% Cr2O3 content) is developed allowing chromium extraction from local chromite in the form of more expensive chromium powder The process of increasing the reactivity of chromite concentrate (with a Cr2O3 content of 53%) as a Preparation of Superconcentrate and Chromium Powder from Chromite Ore

.jpg)

Chromite an overview ScienceDirect Topics

According to data from the International Chromium Development Association (ICDA), global chromite ore and concentrate production totaled 294 metric tons in 2014 (Richard, 2015)Data from the US Geological Survey (USGS) estimated world production in 2014 at 29 metric tons, with South Africa at 15 metric tons, followed by Kazakhstan at 4 metric tons, 2023年10月1日 The chromium (Cr) content of stainless steel originates from recycled scrap and/or ferrochrome (FeCr), which is produced mainly by the carbothermic reduction of chromite oreChemical beneficiation of chromite ore to improve the chromium Direct reduction of chromite (DRC) is a promising alternative process for ferrochrome production with the potential to significantly reduce energy consumption and greenhouse gas emissions compared to conventional Mechanism of the Direct Reduction of Chromite 2024年4月9日 1 South Africa Mine production: 18 million MT South Africa produced 18 million MT of chromium in 2023, down from the 191 million MT produced in 2022Top 5 Chromiumproducing Countries (Updated 2024)

.jpg)

Cleaner Production of Chromium Oxide from Low Fe(II)Chromite

2020年5月19日 Sulfuric acidbased leaching is a promising cleaner method to produce chromium salts, but its feasibility for treating low Fe(II)chromite still remains to be proven A Box–Behnken design (BBD)based set of experiments for sulfuric acid leaching of low Fe(II)chromite was utilized in this work for generating an experimental dataset for revealing the 4 天之前 Chromium is extracted from chromite ore Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4) Companies in South Africa supply chrome ore from the lower and middle group chromitites of the Bushweld complex and from the upper group chromitite seam (UG2) in addition to platinum group mineralsWhat is chromite (chrome) ore and where is it found2022年2月1日 To establish a cleaner production technology of chromium salt, the pressurized leaching process of chromite ore in 60 wt% NaOH solution, subsequent separation of a chromium salt from the leached solution and Cr 2 O 3 preparation from the intermediate product BaCrO 4 were systematically investigated, and a new highly A cleaner method for preparation of chromium oxide from chromite ore 2022年4月27日 hromite is the single commercially viable ore of chromium (Cr) which is chemically known as iron chromium oxide (FeCr 2 O 4) The properties of chromium that make it most versatile and indispensable are its resistance to corrosion, oxidation, wear galling and enhancement of hardenability Chromium is an important alloying metalCHROMITE Indian Minerals Yearbook 2020 IBM

THE ALUMINOTHERMIC PRODUCTION OF EXTRA LOW

2010年11月12日 Thus, the concentration of this ore was found to be useless Therefore, the study was carried out on the low grade chromite ore without concentration 2 EXPERIMENTAL Pilot plant experimental heats were carried out to produce extralow carbon ferrochromium from a domestic low grade chromite ore using the aluminothermic